About Aria Cable Fadak

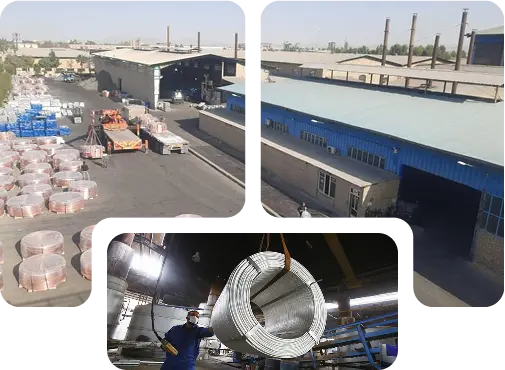

Aria Cable Fadak was established in 2006 with the aim of providing sustainable and specialized raw material supply for the country’s key industries. The company started as one of the leading manufacturers focusing on producing various aluminum and copper products, and today, after years of experience, technical knowledge, infrastructure development, and quality improvement, it has become one of the trusted and prominent names in the country’s industry.

At Aria Cable Fadak, by utilizing the latest global technologies, fully automated production lines, and specialized human resources, we have been able to deliver high-quality products that comply with international standards to the market. Our products include various alloy aluminum billets, aluminum and copper wires, and different aluminum profiles such as semi-spheres and aluminum chips.

The company has two manufacturing plants located in Shokouhieh Industrial Town in Qom and the Special Economic Zone of Salafchegan, which, with high production capacity and advanced facilities, play a significant role in the supply chain of domestic industries. We collaborate with customers in the automotive, steel, wire and cable, and other strategic industries, and have always strived to exceed their expectations.

One of our competitive advantages is the presence of a dynamic research and development (R\&D) unit equipped with modern laboratory instruments. This unit continuously monitors and improves product performance using chemical analysis devices, metallography, tensile testing, electrical resistance measurement, and other quality control instruments. Additionally, intelligent control systems in the production processes reduce waste, increase efficiency, and maintain consistent quality in the products.

Alongside our industrial goals, we are also committed to social and environmental responsibility. Our processes are designed with an approach to reduce energy consumption, reuse recycled materials, minimize pollution, and preserve natural resources. We believe that economic development must be aligned with environmental preservation and the improvement of community quality of life.

Aria Cable Fadak has obtained the following international certifications to enhance quality, safety, environmental management, and customer satisfaction:

IATF 16949, ISO 9001:2015, ISO 45001:2018, ISO 10002:2018, ISO 14001:2015, and IMS.

These certificates demonstrate our commitment to implementing integrated management systems and continuous improvement across all organizational processes.

Additionally, the company utilizes advanced and modern laboratory equipment imported from Germany to conduct highly precise quality control processes, ensuring maximum customer satisfaction.

Our Features

Our Key Features

High production capacity

With a high production capacity, featuring 12 cylindrical furnaces, each with a melting capacity of 35 tons per day.

Strict Quality Control

Equipped laboratory with advanced devices such as spectrometers, optical microscopes, tensile testing, phase analysis, and chemical analysis to ensure product quality.

Manufacturing with advanced technology

Equipped with fully automated and intelligent continuous casting production lines, meeting global standards for high-precision manufacturing.

Specialized workforce

An experienced technical and engineering team in production, quality control, research and development, and technical support.

Quality Should Not Be Just a Slogan

Aria Cable Fadak is the only company in Iran equipped with Continuous Casting Lines for the production of aluminum alloy ingots.

Equipped with advanced and fully automated robots.

Continuous casting is one of the most advanced methods for producing aluminum alloy ingots. This technology is designed to increase productivity, improve quality, and ensure uniformity in the final product, making it an efficient alternative to traditional casting methods.

In this process, molten metal is continuously poured into specially designed molds. As the metal comes into contact with the mold’s cooled walls, it gradually solidifies. The operation is performed without interruption, under precise control of temperature and casting speed, resulting in high-quality, structurally uniform ingots.

Key advantages of this technology include:

Superior surface quality and internal structure

Thermal uniformity and better cooling control

Reduction of shrinkage cavities and structural defects

Higher productivity and savings in time and energy

Minimal production waste and reduced need for secondary operations

This method allows for more accurate control over the metal’s chemical composition and mechanical properties. Thanks to continuous and automated monitoring throughout the process, the produced ingots possess consistent and reliable characteristics, making them ideal for use in high-precision industries.

Another major benefit of continuous casting is the reduced need for post-processing. The smoother surfaces and more precise dimensions of the ingots minimize machining, surface finishing, and other preparatory steps, thus lowering production costs.

Compared to traditional batch casting methods—which are often time-consuming and prone to quality inconsistencies—continuous casting delivers uninterrupted production, higher quality, and better process control.

For companies aiming to produce high-quality, uniform, and cost-effective ingots, adopting continuous casting technology is a strategic decision. It not only boosts efficiency and profitability but also meets the demands of modern industries such as automotive, aerospace, electrical, and construction.

Image Gallery

Get to Know Us Better